Contact Us

Tel:

(+86)021-56883100

E-mail:

shmss@mss-tech.cn

Address:

Room 519, Building 3, Jufeng Plaza, 697-3 Lingshi Road, Jing’an District, Shanghai

Wechat:

SHMSS_

Whats App:

+86 17362163207

Platform URL:

https://shanghaimss.en.made-in-china.com

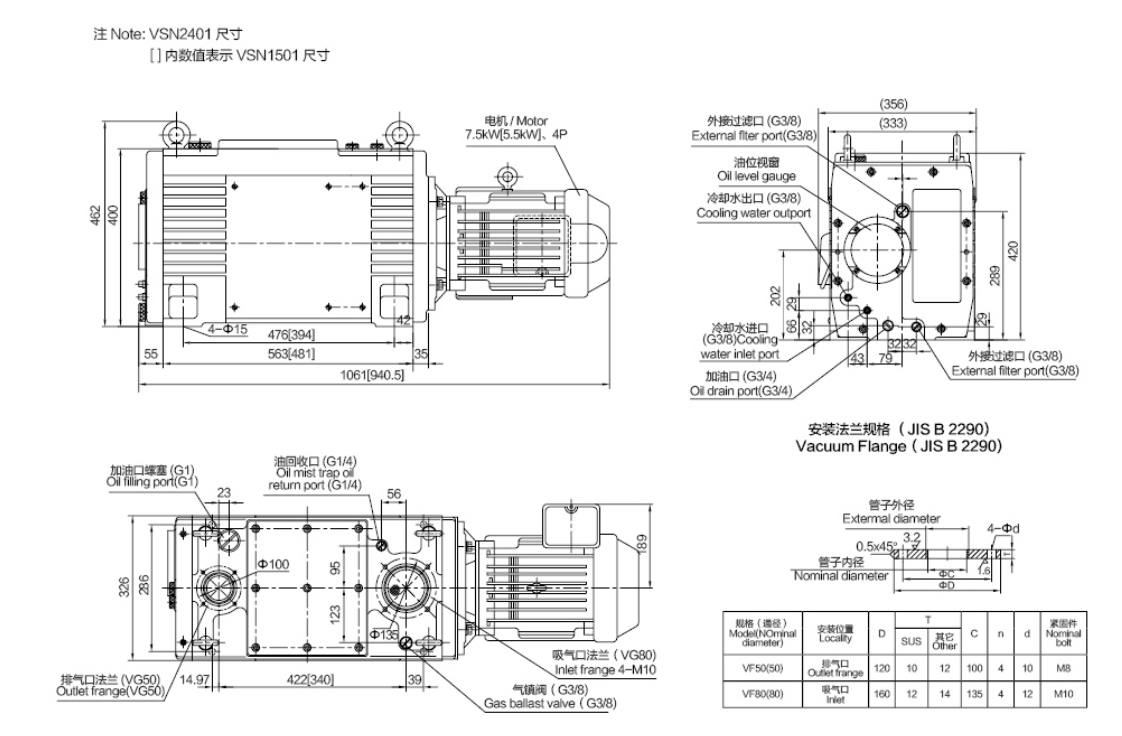

Oil rotary vane vacuum pump(MSS-P-VSN1501 / VSN2401)

- Commodity name: Oil rotary vane vacuum pump(MSS-P-VSN1501 / VSN2401)

- Description

-

Welcome to Shanghai Mengsheng Sheng International Trade

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~▍Features

Compatible with continuous operation at high pressure (patent pending)

A forced oil circulation system inside the pump enables stable operation even at high inlet pressures. When equipped with the optional oil mist trap and oil return mechanism, these heat- resistant pumps can run continuously at pressure equal to or below atmospheric pressure

Quiet-running performance

The use of mechanism that reduces operating noise when pumping at ultimate pressure, allows noise levels to be reduced 74dB (characteristic A) for both the VSN1501 and VSN2401 models (Values measured at ultimate pressure while using an oil mist trap at a distance of 1 meter to the side of the pump)

Low vibration

The special single-stage vane design used in this pump permits the use of a high-speed motor (1500 rpm at 50 Hz) that helps to significantly reduce vibration levels in a low frequency range of the spectrum, where the transmission of vibrations through buildings can be a problem,

This pump can largely eliminate the need for special foundation work and can be more easily installed on the upper floors of most buildings.

Outstanding ease of maintenance

Checking, adding, and changing oil are done at one side on the pump to facilitate greater ease in performance routine maintenance and inspection. Amount of time between oil additions is extended for oil capacity to be changed over a range of 8 to 1.5 liters.

▍Applications

· Evaporation, sputtering, and ion plating

· Gas substitution, back-filling and vacuum heat insulation.

· Vacuum heat treatment furnaces, sintering furnaces, and brazing furnaces.

· Vacuum drying, freeze drying, and vacuum degassing.

· Automated leak testing, vacuum molding and vacuum casting

· Vacuum packing, vacuum adsorption, vacuum transport and others.

▍Specifications* 1.The value above is measured with Pirani gauge

* 2.G.V is the abbreviation of gas ballast valve

▍Dimensions

▍Pumping rate curve

Pressure

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~Your satisfaction and positive feedback is very significant to us.

Thank you! Have a nice day!

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products