Contact Us

Tel:

(+86)021-56883100

E-mail:

shmss@mss-tech.cn

Address:

Room 519, Building 3, Jufeng Plaza, 697-3 Lingshi Road, Jing’an District, Shanghai

Wechat:

SHMSS_

Whats App:

+86 17362163207

Platform URL:

https://shanghaimss.en.made-in-china.com

MSS-A-XUY-AT

- Commodity name: MSS-A-XUY-AT

- Description

-

Welcome to Shanghai Mengsheng Sheng International Trade

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

VM Algorithm Development Platform

VM Algorithm Development PlatformThis device can meet machine vision applications such as size measurement, barcode recognition, appearance defect detection, color recognition, etc,

Complete custom development through the control and data acquisition interfaces provided by the VM algorithm development platform.

The algorithm development platform provides over a thousand independently developed image processing operators and various interactive development tools,

Supports multiple image acquisition devices, capable of meeting the requirements of contour size detection, recognition, and code reading in the field of machine vision

Requirements for class and appearance defect detection.

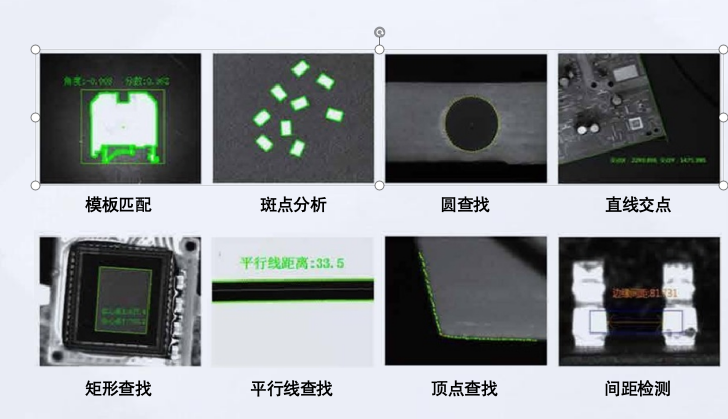

Outline dimension detection

Efficient positioning tool matching tool that can overcome the differences caused by sample translation, rotation, scaling, and different lighting conditions,

Quickly and accurately locate the positions of geometric shapes such as circles, lines,

spots, edges, vertices, etc. Provide location information and presence/absence

Information can be applied to robot guidance and other visual tools.

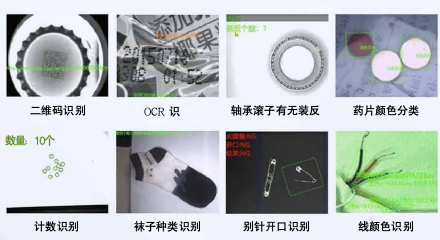

Identify code reading classification

Provide continuous, accurate, and high-speed reading of ID information required for component tracking: OCR algorithms based on deep learning can adapt to the recognition of complex backgrounds, low contrast, deformations, and other characters; Various product recognition algorithms can identify information of multiple formats, different positions, angles, and lighting conditions, effectively overcoming the impact of image distortion.

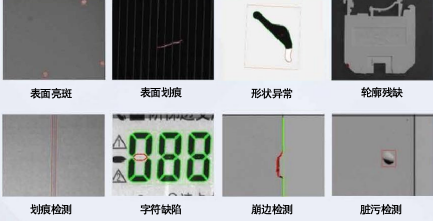

Appearance defect detection

Accurately identify defects on the surface, shape, and contour of the workpiece: capable of detecting surface scratches and spots, and can overcome interference from surface texture, color, and noise of the workpiece; Accurately detecting the shape and contour defects of workpieces can overcome the interference of burrs, colors, and noise. A reliable tool for comparing standard parts to locate small differences in workpieces.

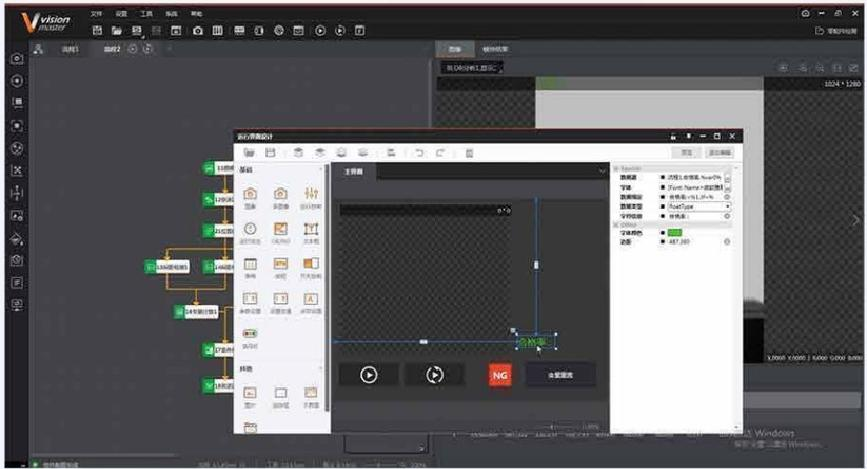

Graphical interface

The VM algorithm development platform provides a fully graphical interactive interface, with intuitive and easy to understand functional icons, simple and easy-to-use interaction logic, and drag and drop operations that can quickly build visual solutions. Excellent software interaction and visual design, outstanding user experience.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~Your satisfaction and positive feedback is very significant to us.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~Your satisfaction and positive feedback is very significant to us.

Thank you! Have a nice day!

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products